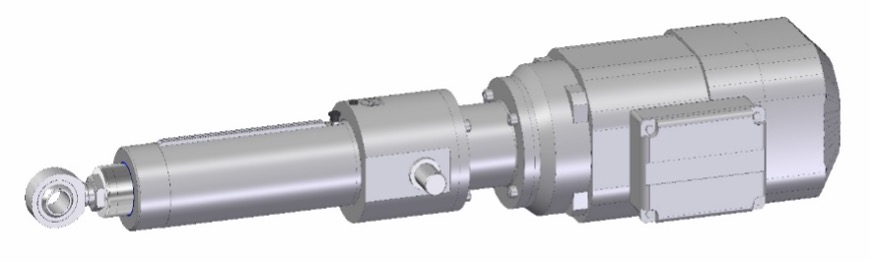

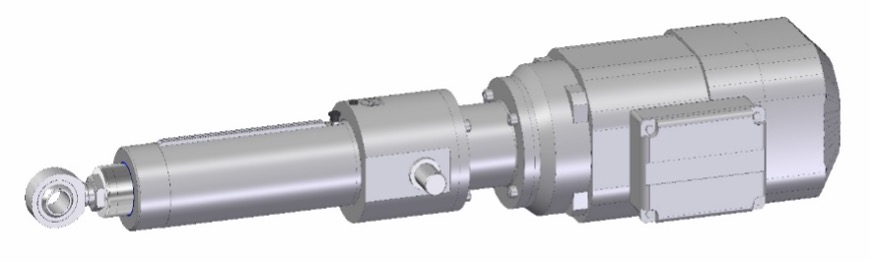

ADE MST & MSK electric actuators "tailor-made" to specifications, specially adapted to high-performance, demanding industrial applications or applications requiring operation in severe conditions or environments!

Because the level of energy consumed by industrial production equipment has now become an important selection criterion, put all the chances on your side by using electric actuators for your force translation movements!

The advantage of electric actuators over other systems, such as hydraulic or pneumatic systems, which require energy production plants that often operate full time, is that they only need electrical energy to translate the movement. The position is then maintained by locking the mechanical translation system with an undercurrent brake, which can maintain the position indefinitely without the need for energy. Thanks to their kinematic design, electric actuators with ball screws are also extremely energy-efficient!

Another advantage of BINDER MAGNETIC electric actuators is that no fluids are used. Instead, a specific, sealed lubrication system for the nut/screw translation system is used, making it possible to install them in equipment where any risk of oil leakage must be absolutely ruled out (e.g. food processing, river or maritime environments, steel industry environments with molten metal, nuclear environments, military environments, etc.).

This range of high-performance industrial electric actuators is specifically designed for demanding applications requiring, individually or in combination, one or more of the following technical features: High push/pull forces, Multiple position control, High operating rates, High linear speed.

|

Main features of MST & MSK cylinders

|

Possible strokes and forces

|

Options

|

Mounting accessories

|

- Ultra-robust, high-performance construction with a wide range of versions and options that can be configured to meet your specifications, enabling operation under severe constraints and in aggressive environments up to IP 68.

- 2 possible motion translation systems:

A) MST trapezoidal screw for applications requiring high force but low speed.

B) By ball screw for force applications requiring speed and positioning accuracy.

- 230/400 V3AC asynchronous motor or DC brushless servomotor.

- 100% duty cycle suitable for very high speed operation.

- Unlimited number of positions with the addition of an encoder or resolver.

- Maintenance-free cylinder, reduced mechanical travel system to be greased once a year.

- Self-locking safety actuators (irreversible) or vice versa (reversible) as required.

- Easy to install, can be upgraded by changing the control parameters.

- Energy-saving electric actuators.

|

- Stroke: from 100 mm to 3000 mm

- Force: from 50 daN to 25000 daN

- Speed: from 0.5 mm/s to 900 mm/s

|

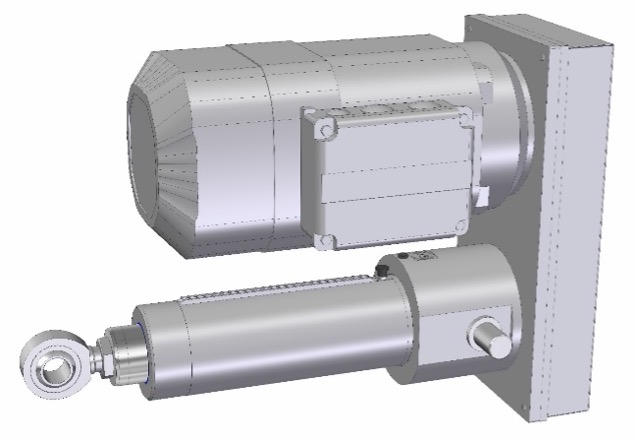

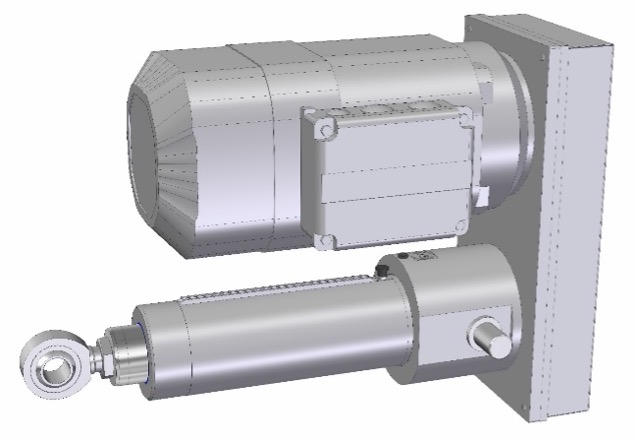

- 4 ways of mounting the direction of the motorisation, depending on the space required.

- Force can be limited by means of an electromechanical overload limiter in the pull/push direction to protect the mechanical system in the event of overload or accidental blockage.

- Equipped with 2 limit switches in series, a 3rd intermediate limit switch can be fitted.

- Encoder or motor resolver for precise, unlimited control of the number of positions.

- Holding brake and safety device to lock the position in the event of a power failure.

- Speed adjustable within a given range by frequency variation for 3AC versions or by electronic commutation control for brushless servomotor versions.

- Non-exhaustive list of options, many other options and versions available => on request.

|

- Fixing bearings for trunnions

- Rod clevis or fork clevis

- Connecting base for rear clevis

|