TECHNICAL EXPLANATIONS OF ADE MS10 T ACTUATORS

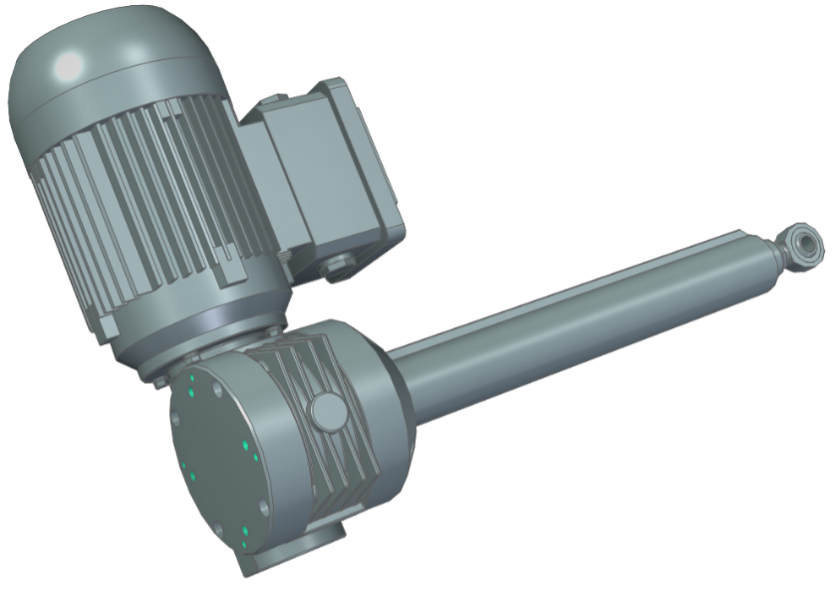

The MS10 T series actuators are predefined by assembling standard components like a construction kit. They are based on a trapezoidal screw drive mechanism and an integrated worm gear reducer system, making them the most economical, reliable, robust and maintenance-free solution for push/pull movements in many areas where speed and positioning accuracy requirements are not the most stringent, but where the electric actuator solution offers numerous advantages thanks to its cleanliness, reliability and ease of use.

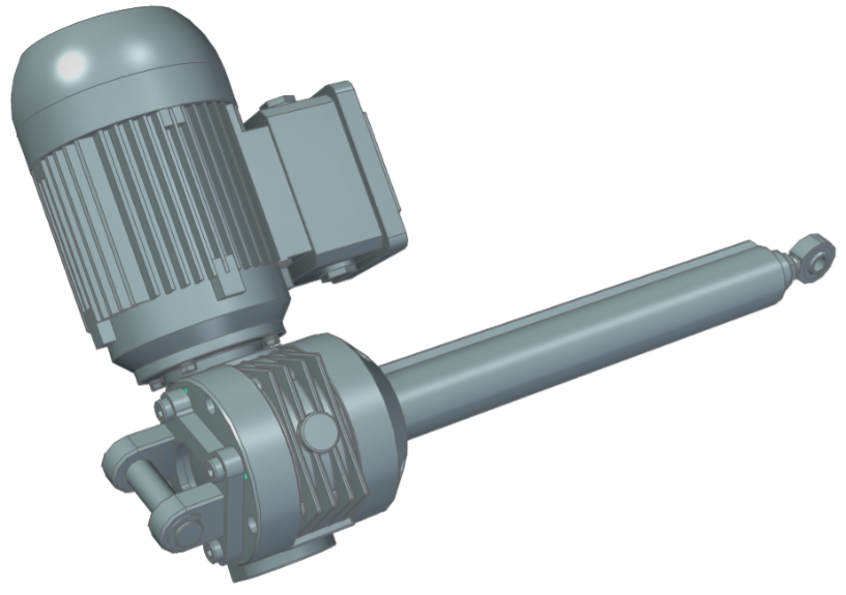

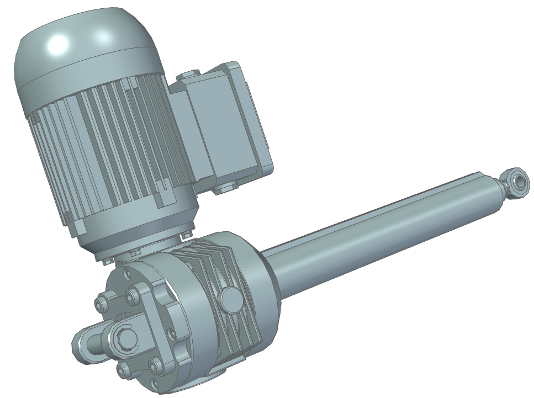

The screw reducer design allows the motor to be mounted perpendicularly, thus reducing the mounting centre distance. 2 types of mounting on the actuator are possible: the rear clevis or an optional 2-pin mounting at the rear of the actuator.

Stroke can be infinitely adjusted over the entire length using the MZT7 limit switch.

Available exclusively with 230/400 V-3 AC or 24 V DC three-phase induction motors.

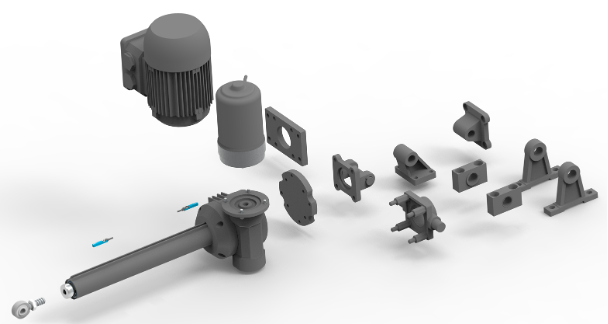

1 size of actuator is available and can be quickly configured by you to meet a wide range of movement applications in industrial equipment.

- MS10 T with a force of 10 to 1000 daN and stroke in 100 mm increments from 100 to 500 mm.

- These actuators are delivered in a complete kit and can be quickly assembled in your own workshop.

|

Main features of the MS10 T actuators |

Possible strokes and forces |

Options |

Mounting accessories |

|

|

|

|

3D files of these actuators can be downloaded for strokes between 100 and 500mm for the 3 most common versions (other versions on request).

1) ADE MS10 T actuator - 45° clevis

2) ADE MS10 T actuator - 0° clevis

3) ADE MS10 T actuator - Fixed mounting on body and ball-and-socket joint on rod