TECHNICAL INFORMATIONS OF ATN SYSTEM

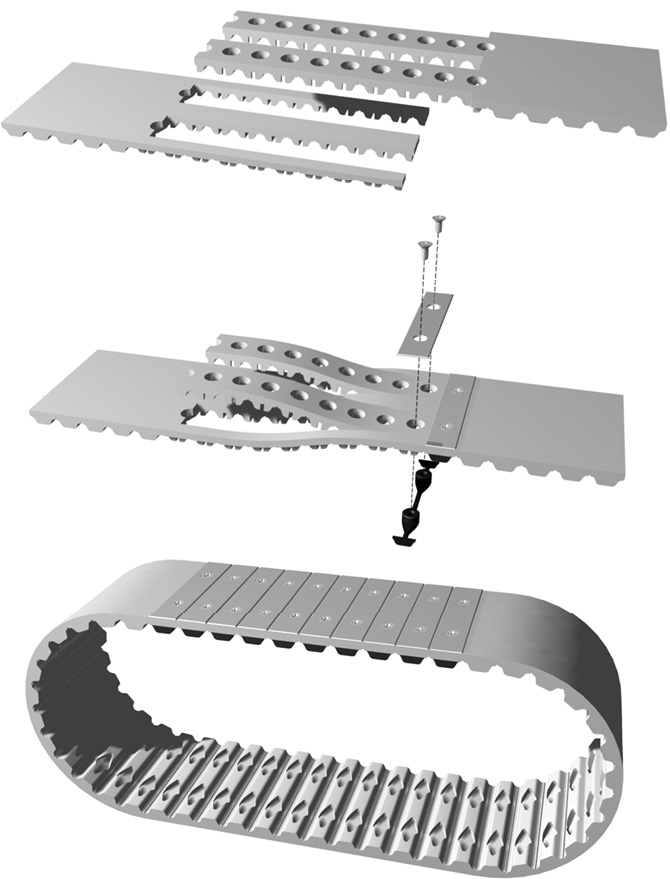

SCREW-ON PROFILES IMPLEMENTATION

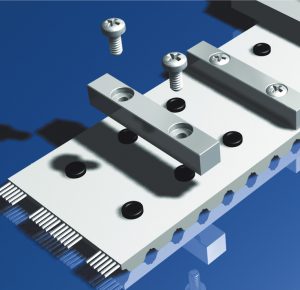

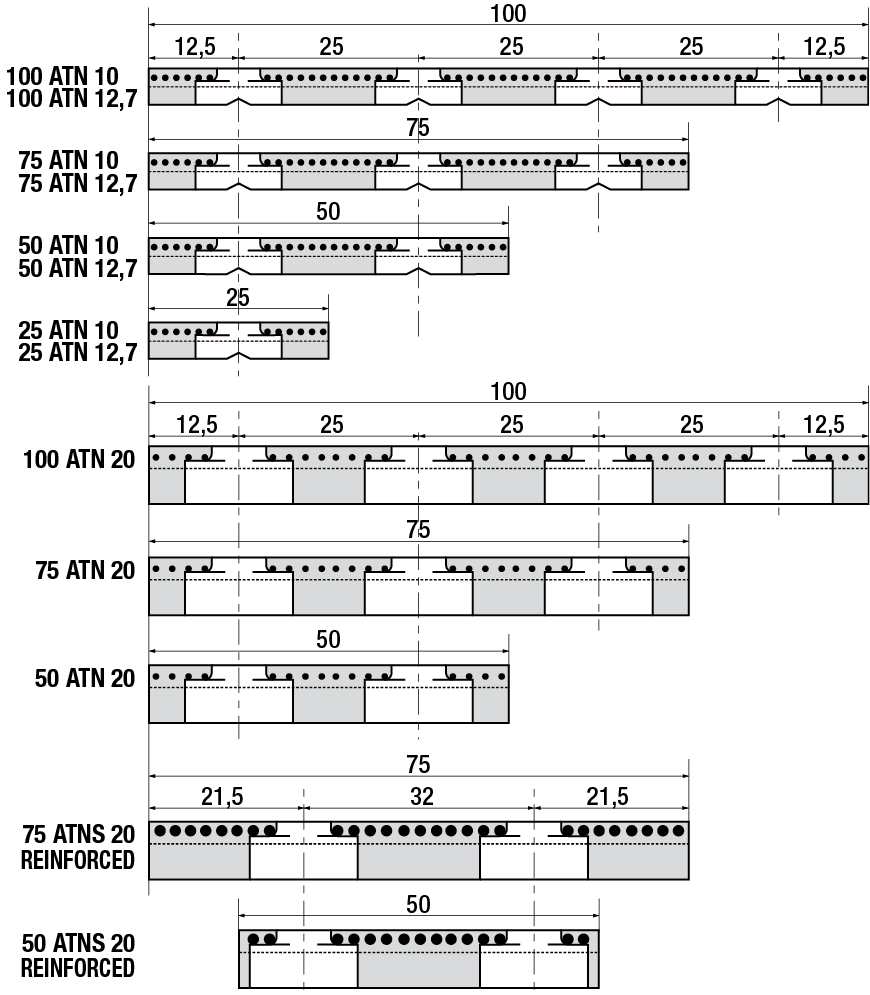

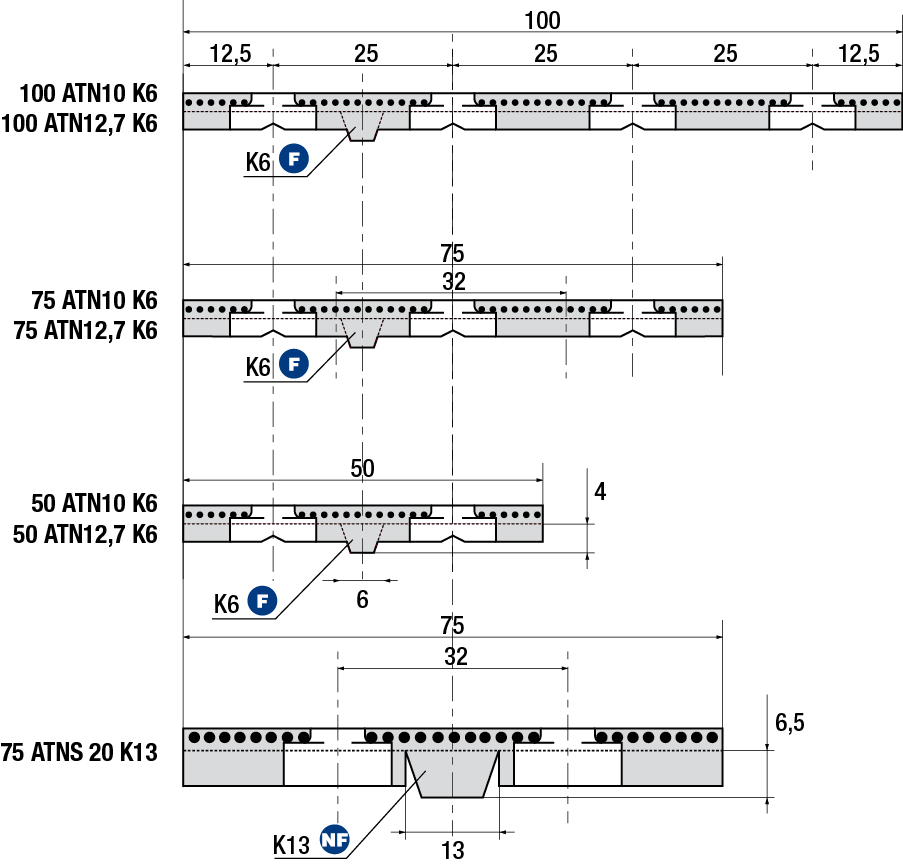

The ATN modular belt concept enables profiles to be attached with the aid of insert parts. The fastening centre distances are multiples of 10, 12.7 and 20 mm according to the belt pitch.

1 / Advantages

1.1 Highly modular

- Possibility of fitting standard profiles or specific profiles unique to the user, in all materials.

- Possibility during use of equipping the belt with different profile profiles or of modifying a fastening centre distance without removing the belt.

- Possibility of fastening different types of profiles on a standard base.

1.2 Very easy to use

- Fitting directly by the user without specific tools or additional machining.

- Possibility of joining “open belts” on the machine using mechanical joint systems.

- Use of standard AT10, AT20 pulleys (except for the ATN12.7 pitch, for which the pulleys are “according to drawing” only: consult us).

- Seal removal using the piercing tool and the mounting plate

2 / Specific details

- The belts are systematically produced with cavities in each tooth.

- The backs of the belts are flat. The holes are closed off by a 0.2 mm thick seal.

- The insert parts must be inserted by hand into the teeth.

- The profiles are fastened with tapping screws or M screws

- The profiles can withstand the transmission of high forces.

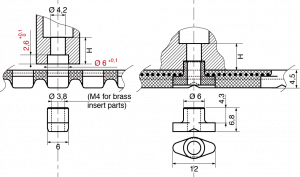

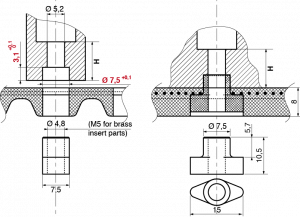

- Brass and stainless steel insert parts with M4 (ATN10, ATN12.7) and M5 (ATN20, ATNS20) threads are available.

- EJOT Delta PT screws for synthetic materials are available.

- M4 x 12 and M5 x 16 screws in stainless steel and galvanised steel are available (can also be used in brass and stainless steel insert parts).

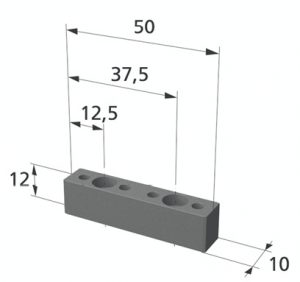

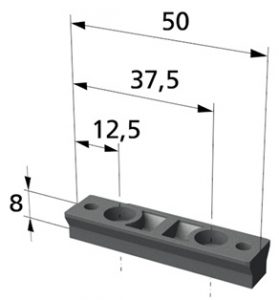

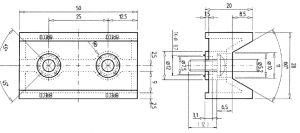

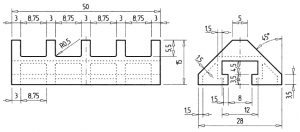

ATN10 and ATN12.7 profiles

In red: dimensions necessary for good assembly

ATN belt

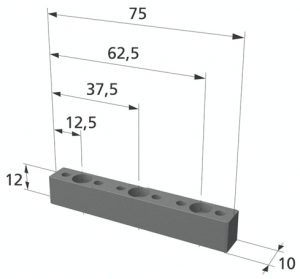

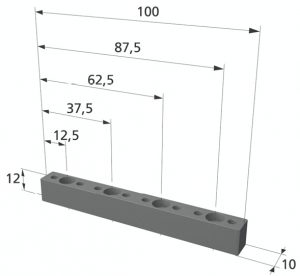

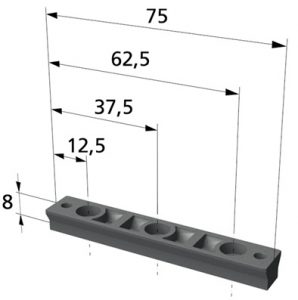

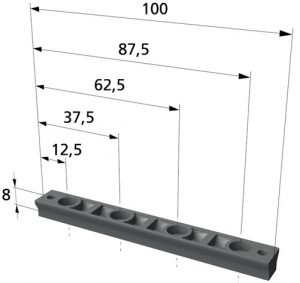

ATN20 and ATNS20 profiles

Self-guiding ATN belt

(note the off-centre position of the guide profile for widths 75 and 100 ATN10 and ATN12.7)

: slit

: not slit

3 / Insert parts

High-strength polyamide

Polyamide fastening inserts call for the use of tapping screws which are available in stock (see table below). The use of other non-approved tapping screws may cause deformation of the inserts or a reduction of the nominal tension force.

Brass and stainless steel

These inserts are provided with a threaded locating hole, allowing the use of standard M4 (ATN10/12.7) and M5 (ATN20) screws.

Characteristic of insert parts

|

Type |

Material |

Profile material |

Tightening torque (N.cm) |

Axial force (N) |

Screw type

|

|

ATN10 & ATN12,7 |

polyamide |

polyamide |

70 |

100 |

taping |

|

metal |

70 |

100 |

|||

|

PU |

50 |

40 |

|||

|

brass |

polyamide |

100 |

170 |

M4 |

|

|

metal |

100 |

320 |

|||

|

stainless steel |

polyamide |

100 |

170 |

||

|

métal |

100 |

320 |

|||

|

ATN20 & ATNS20 |

polyamide |

polyamide |

100 |

160 |

taping |

|

métal |

100 |

160 |

|||

|

PU |

80 |

40 |

|||

|

brass |

polyamide |

150 |

240 |

M5 |

|

|

metal |

150 |

490 |

|||

|

stainless steel |

polyamide |

150 |

240 |

||

|

métal |

150 |

490 |

4 / Screws

|

Galvanised steel screw DIN 7984

|

Stainless steel 1.4301 screw DIN 7984

|

Hardened steel PT10 tapping screw |

|

|

ATN10 / ATN12,7 / |

M4 x 8 |

VA M4 x 8 |

Z40 x 8 |

|

M4 x 12 |

VA M4 x 12 |

Z40 x 12 |

|

|

M4 x 16 |

VA M4 x 16 |

Z40 x 16 |

|

|

ATN20 / |

M5 x 12 |

VA M5 x 12 |

Z50 x 12 |

|

M5 x 16 |

VA M5 x 16 |

Z50 x 16 |

|

|

M5 x 20 |

VA M5 x 20 |

Z50 x 20 |

5 / Option: connection with lock system

Belts are normally joined by welding. We nevertheless suggest a lock system for complex installations.

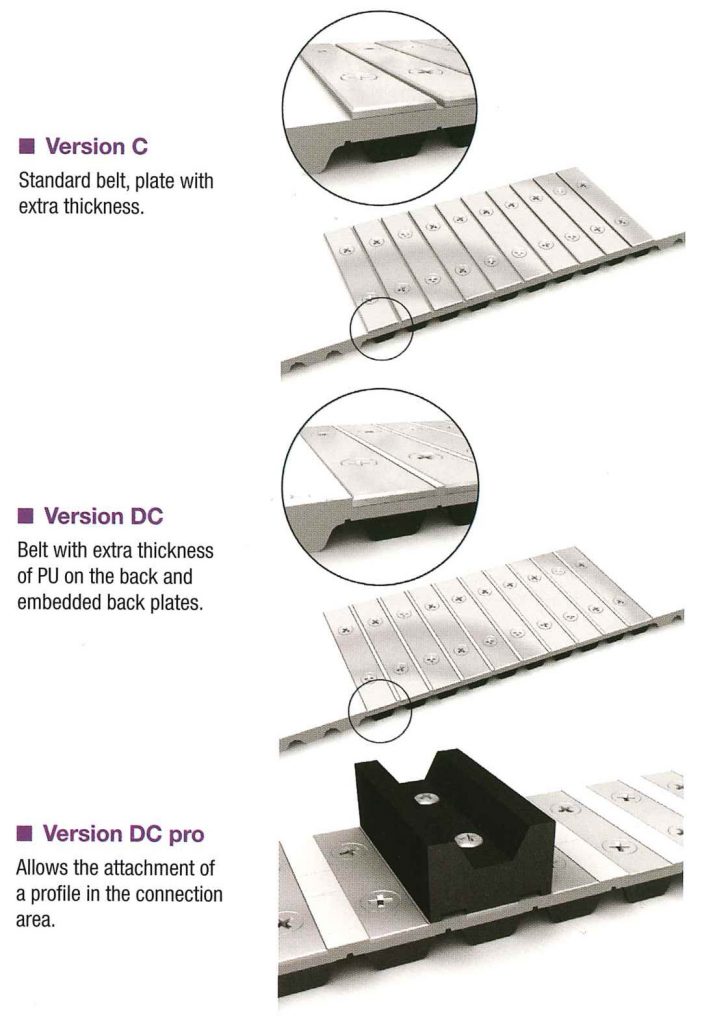

Belt versions

For the DC and DC PRO versions the thickness of the belts is increased by 0.9 mm.

The mechanical joint system for ATN belts enables the belt to be quickly changed without removal from the machine.

The belt can be supplied pre-assembled or ready for assembly with a “connection elements” kit.

Version that can be produced:

|

Version C |

Version DC |

|

|

ATN10 |

X |

X |

|

ATN12,7 |

X |

X |

|

ATN20 |

X |

|

|

ATNS20 |

X |

|

|

ATN10 K6 |

X |

X |

|

ATN12,7K6 |

X |

X |

Force transmittable by the mechanical locks

|

Belt widths(mm) |

50 |

75 |

100 |

|

ATN10 – ATN10 K6 |

750 N |

1 150 N |

1 500 N |

|

ATN12,7 – ATN12,7 K6 |

750 N |

1 150 N |

1 500 N |

|

ATN20 |

1 000 N |

1 500 N |

2 000 N |

|

ATNS20 |

1 000 N |

1 500 N |

– |

Length of mechanical locks

Applicable regardless of version (C, DC or DC PRO):

For ATN10 and ATN12.7: 10 teeth, 9 pitches.

For ATN20 and ATNS20: 9 teeth, 8 pitches.

6 / Fitting accessories

Piercing tool

The piercing tool makes it easy to remove the 0.2 mm thick seal which closes off the back of the belt before the inserts are attached. We are also able to remove seals in series at our factory.

|

Stock | Length (mm) | Ø(mm) | |

| ATN10 & ATN12.7 | Yes | 70 | 6 | |

| ATN20 & ATNS20 | Yes | 70 | 7.5 |

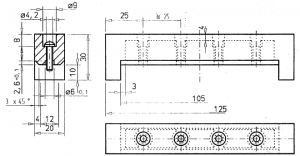

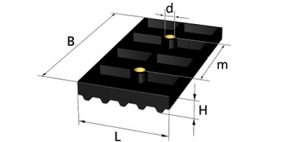

Mounting plate

Toothed polyamide plates are designed to help attach the available inserts. This plate prevents the insert from rotating and the belt tooth from deforming when the profile is tightened on the back of the belt.

|

Stock | L | B | h | m | d | |

| ATN10 | Yes | 50 | 100 | 12 | 50 | M5 | |

| ATN12.7 | Yes | 63.5 | 100 | 12 | 50 | M5 | |

| ATN20 | Yes | 100 | 100 | 14 | 50 | M5 |

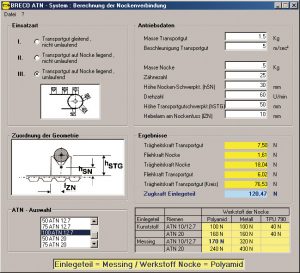

7 / Dimensioning program

The calculation program ATN-CONNECT allows you to dimension profiles correctly. You can download the program from our website http://www.binder-magnetic.com.

8 / Library of profiles

|

SIMPLE GEOMETRIC PROFILE (INDEXING / SUPPORT)

|

SIMPLE GEOMETRIC PROFILE (INDEXING / SUPPORT)

|

SIMPLE GEOMETRIC PROFILE (INDEXING / SUPPORT)

|

|

|

|

|

|

|

|

Reference 1.001.008 |

Reference 1.001.009 |

Reference 1.001.010 |

|

|

ASSEMBLY PROFILE

|

ASSEMBLY PROFILE

|

ASSEMBLY PROFILE

|

|

|

|

|

|

|

|

Reference 1.001.005 |

Reference 1.001.006 |

Reference 1.001.007 |

|

|

SIMPLE GEOMETRIC PROFILE (INDEXING / SUPPORT)

|

SUPPORT PROFILE

|

|

SUPPORT PROFILE (STANDARD / SPECIFIC)

|

|

|

|

|

|

|

For 50ATN10 and 50ATN12.7: Reference 1.020.003 |

For 50ATNS20: Reference 1.020.004 |

||

|

Reference 1.020.005 |

Reference 1 |

||

Latest news

- Apr 17, 2025

10 years of success for BRECOprotect® food belts!

- Feb 06, 2025