TECHNICAL INFORMATIONS OF CONVEYING APPLICATIONS

CONVEYING APPLICATIONS

General design

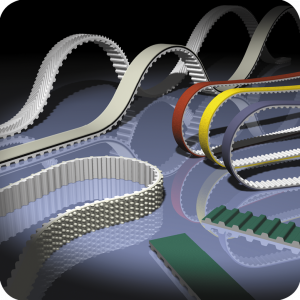

Your conveying, transport or positioning project combines abrasion resistance, positioning precision and modularity: BINDER magnetic offers a full range of belts with coatings, specific machining and profiles which are welded or secured by the ATN system.

The choice of belt depends on the load to be conveyed, or more exactly on the distribution of the load on the belt and on the friction coefficient between the slider bed and the belt.

Welded BRECO® belts (V) are generally used for transport applications; the characteristics of these belts are specified in the chapter “Linear Technologies”.

Coated belts

Linear BRECO® and BRECOFLEX® belts can be fitted with different types of coatings. They can also be used in a wide range of applications in transport technologies depending on whether adherence or, conversely, sliding with good abrasion resistance is required.

It is, however, important to note that the reduced number of tension members in the join area of welded BRECO® belts (V) reduces by half the nominal transmittable force: the elements are described in the chapter “Linear Technologies”.

Machined belts

BRECO® and BRECOFLEX® belts can be reworked to suit the coating and/or the function to be carried out. We can deliver all longitudinal or transversal forms as well as machining that crosses the belt.

Belts with profiles

BRECO® and BRECOFLEX® belts can be produced with profiles which are welded or attached with our ATN system to suit the requirements and the loads to be conveyed.

1 / Dimensioning

Conveying belts must preferably be driven in the positive direction to avoid slip.

Calculation of the tangential force Ft

The tangential force Ft applied to the drive system can be determined as from the global transported load:

Ft = 9,80.m.µ + m.ү

Ft: tangential force (N)

m: mass of product to be transported (kg)

µ: friction coefficient between the timing belt and the sliding bed

γ: acceleration (m/s2)

The following values can be used as friction coefficients µ:

- Steel/PU 92 Shore A: 0.6 – 0.7

- Steel/PAZ: 0.2 – 0.4

- PE/PU: 0.3 – 0.4

The values of the friction coefficients generally demonstrate very high variations. We recommend that you carry out tests. (Information without obligation).

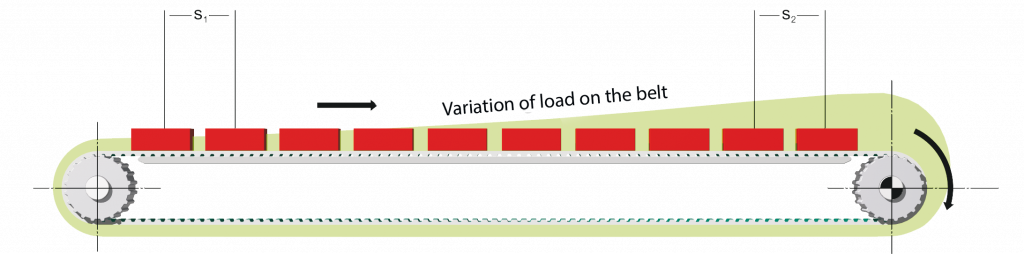

Notes on elongation:

The elastic elongation of a belt is dependent on its stiffness and is proportional to the load. Elongation will therefore be higher in S2.

Distance S1<S2

Pre-tension force

The pre-tension force in a conveyor belt must be regulated in such a way that a residual tension is conserved in the unloaded span. The applied pre-tension force must be:

Fpt > 0,5.Ft

Calculation of the belt width b

b (mm)= (10.Ft (N))/(Ze.F_(t⁄Z) )

Ft: tangential force (calculated)

Ft/z: force transmittable by the teeth

Ze : number of teeth in mesh for welded belts. Ze max. : 6 teeth

The following condition must be satisfied for a welded belt:

FN welded= FN/2>Ft+Fpt

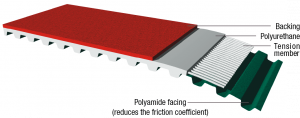

2 / Coatings

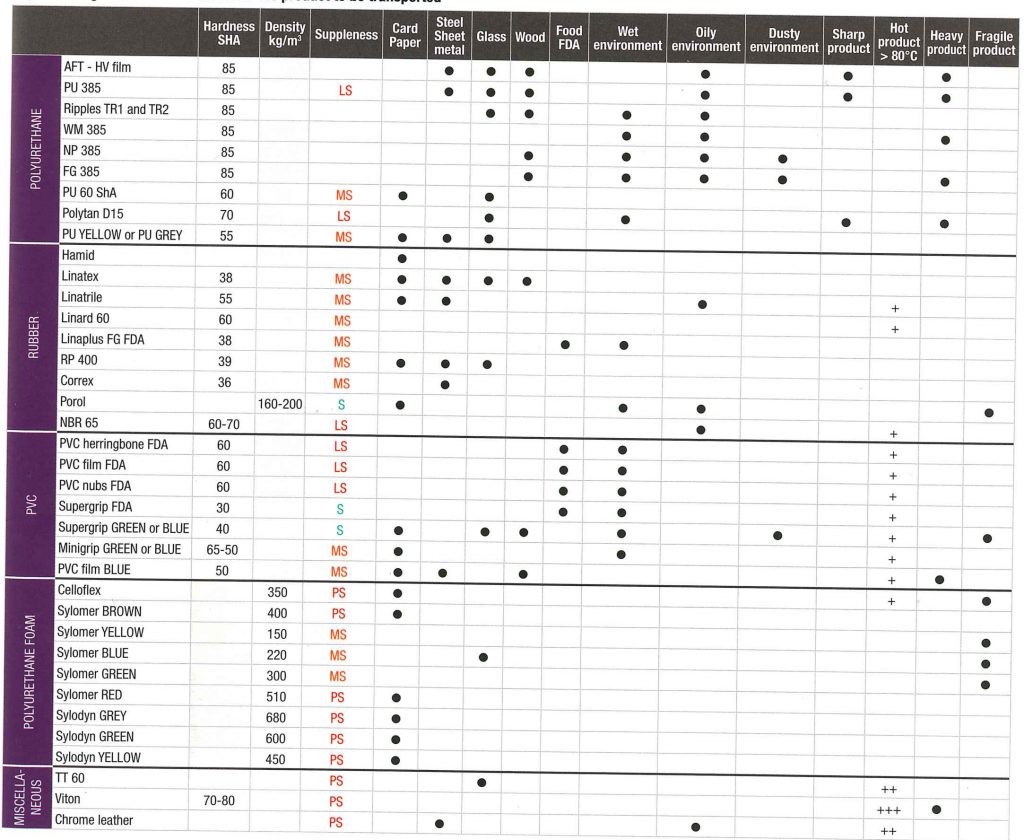

The choice of coating is dependent on the characteristics of the parts to be transported and on the required level of adherence:

- High adherence for high-performance transport,

- Low adherence to reduce the transmission of power,

- Soft coating for fragile objects,

- Hard coating for sharp-angled objects.

Machining can be performed on the back or the toothed side of the belt to meet specific needs. Notches made in very thick coatings, for example, enable the flexibility of the belt to be preserved.

Structure of a belt

Friction

The friction of the belt on a support produces heat which increases with the weight of the objects being transported. It is therefore important to choose the base of the support well to reduce the level of friction to maximum effect. The sliding bed must ensure a good degree of heat dissipation under high pressures.

The friction values are dependent on the temperature: they increase when the temperature increases and decrease when the temperature is around zero.

Resistance to chemical agents

The resistance of each component of a coated belt must be considered separately on the basis of each application.

The resistance depends, among other things, on the pH, the concentration and the temperature of the chemical agents, and on the period of time that the fluid is in contact. Thus, simple oils generally do not have any negative effects on a belt. However, oil additives together with temperatures in excess of 40°C can shorten the service life.

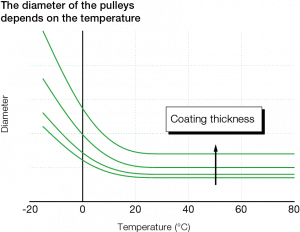

Influence of temperature

When hot parts are transported (temperature above 80°C), it is necessary to ensure that the duration of contact is as short as possible to prevent the coating structure from exceeding 80°C.

A belt with coating can resist a hotter load over a short distance or for a short period on condition that adequate cooling is provided for the rest of the run.

The resistance of the teeth is slightly reduced for temperatures above 60°C. It is necessary to provide additional protection only in the event of increased load on the teeth.

The flexibility of the coating and that of the belt are reduced at low temperatures.

Larger pulley diameters must therefore be chosen. Contact us for further advice on this subject.

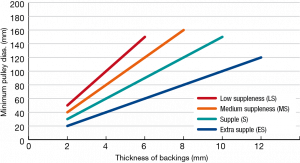

Minimum pulley diameter as a function of the thickness of the coating

The pulleys must have a minimum diameter which depends on:

- the thickness of the coating,

- its degree of suppleness,

- its resistance to cracking/tearing,

- the temperature.

Maintaining this diameter determines the service life of the coated belt.

The coating can be slit transversally to increase its suppleness.

Comments:

- Given values for an ambient temperature of 20°C

- The suppleness of each coating is specified on the following pages

Rapid coating selection table based on the product to be transported

Latest news

- Nov 13, 2025

Increased productivity for BINDER MAGNETIC

- Oct 15, 2025