Innovation is vital in order to be competitive in the medical equipment market. It is also necessary to guarantee irreproachable manufacturing quality and ensure high production volumes.

In France, we support manufacturers of analytical equipment and leaders in the profession. As of the equipment development phase, we supply them with complex belt drives and electromagnetic components. Thanks to its extensive portfolio, BINDER MAGNETIC possesses a wide range of solutions for this extremely demanding market that requires a guarantee of high, sustained and reliable throughput.

Binder Magnetic can help you, for example, to:

-

Ensure sustained throughput

-

Benefit from minimum maintenance

-

Develop made-to-measure products for your applications

-

Ensure the reliability of your processes

-

Miniaturize the footprint of your drive mechanisms

OUR SOLUTIONS

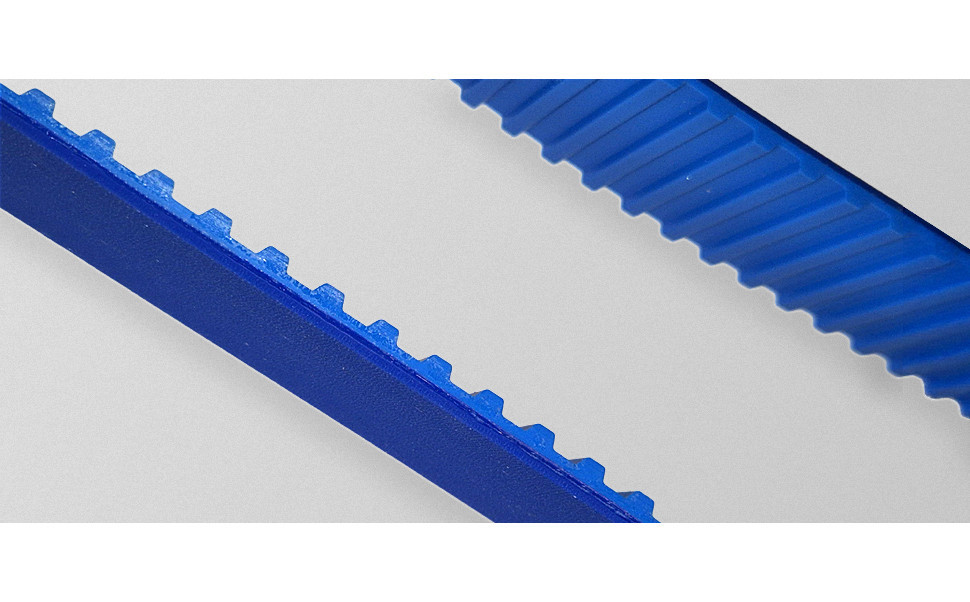

The most precise belts on the market

In the medical field, moulded belts with specially shaped profiles are used to transport the tubes of blood samples into the analysis machines. Special polyurethanes and appropriate cords with specially designed cut-outs make it possible to ensure high throughputs while also guaranteeing reliability and precision.

The SYNCHROFLEX and BRECOFLEX moulded belts in pitches T2 and AT3 are used in the majority of applications required in order to:

-

Transport the tubes

-

Position the specimen bottles opposite the analysers

-

Empty the specimen bottles at the end of the analysis

Electric rams to facilitate linear movements

Radiology or examination tables are raised and lowered electrically using programmable, easy-to-install electromechanical rams.

Stainless steel materials, high protection levels and low energy consumption are necessary in order to ensure long equipment service lives in aseptic environments.

Miniature electromagnetic actuators

For sample analysis, the robots are equipped with linear electromagnets and KENDRION and NAFSA holding magnets so that they can perform millions of operations with absolute reliability. While doing this, they consume only minimum electrical current when:

-

Moving tubes

-

Holding items in position

-

Ejecting nonconforming products