The BRECO® ATN welded joint system is a modular concept for assembling coaches using fasteners. Fixing centers are linked to belt pitches which are multiples of 10, 12.7 and 20 mm. This belt can also be equipped with a mechanical joining system.

The BRECO® ATN mechanical joint belt is a mechanical assembly system that saves time and freedom of action. With a very high resistance, it is therefore available for the entire ATN belt range.

The BRECO®Protect welding junction belt, dedicated to food applications, is highly resistant to aggressive environments. The belts are FDA compliant according to 21CFR regulations and comply with the migration tests according to the European directives.

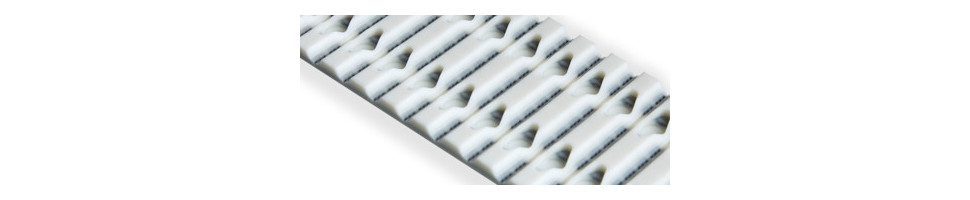

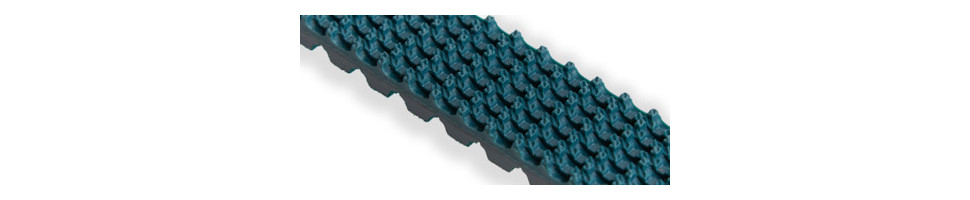

The self-guided BRECO® belt is welded together and is especially suitable for conveying flat products. In particular, it is available in a wide variety of steps / profiles with a K6 or K13 guide profile and can be upgraded with cleats or cladding.

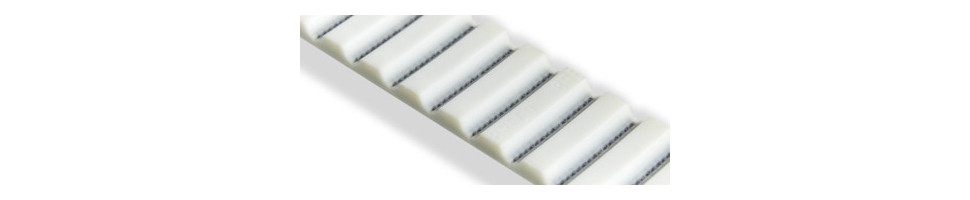

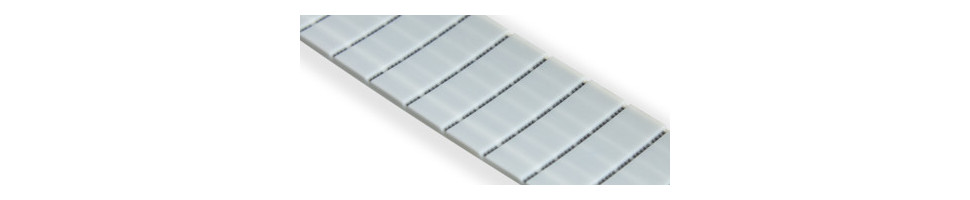

The BRECO® Standard welded joint belt is suitable for conveying or indexing applications combining positioning accuracy and modularity. It is also available in a wide variety of steps / profiles and can be ennobled with cleats or cladding.

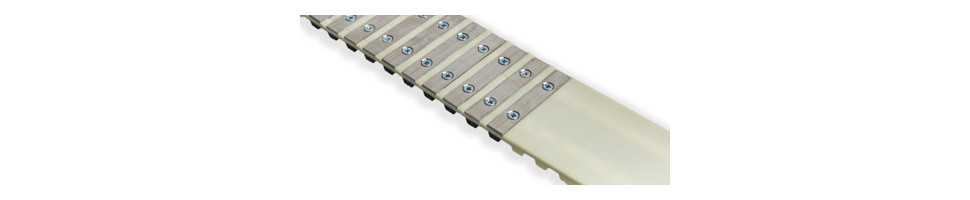

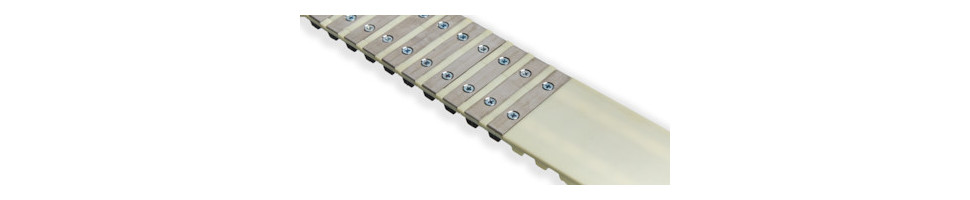

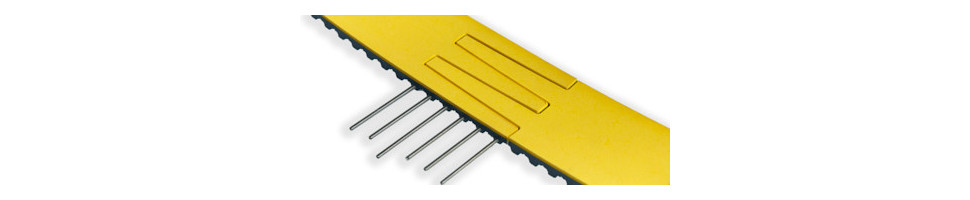

The standard Pinlock BRECO® belt is equipped with a quick assembly system designed for a change in record time and total freedom of intervention for your teams. The PINLOCK can be used with belts with 6 or 10 PIN coating depending on the load to be conveyed.

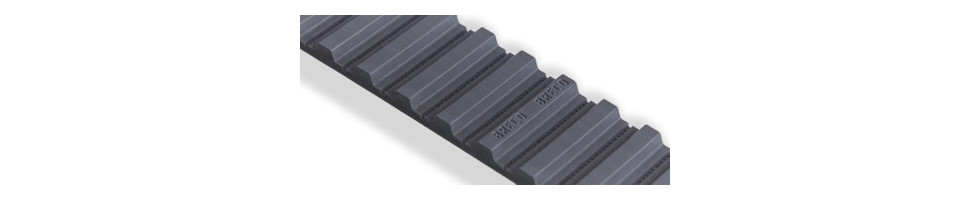

The mechanical joint BRECO® belt is a mechanical assembly system that saves time and freedom of action. With a very high resistance it is thus available to profiles T10 and AT10.

The welded BRECO®Basic belt has been specially developed for simple conveying applications that do not require positioning accuracy.

The BRECO® Pinlock Basic Belt is equipped with a system for simple conveying applications requiring no precision. The PINLOCK can be used with belts with 6 or 10 PIN coating depending on the load to be conveyed.

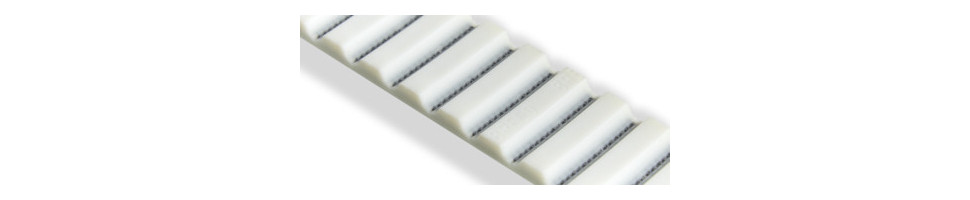

The BRECO® Basic belt with coating has been developed for standard applications in the transport of flat products in areas such as wood and glass processing. It is available with PUGelb, Supergrip, AFT2 and TR1 coatings.

The Basic Belt with Coating is equipped with a threaded rod connection system that has been specially designed for the quick change of conveyor belts for flat products. Thus, it is available with PUGelb, Supergrip, AFT2 and TR1 grooved coatings.

The BRECO® not welded joint thumb belt is especially suitable for machines with indexing linked to the pitch.

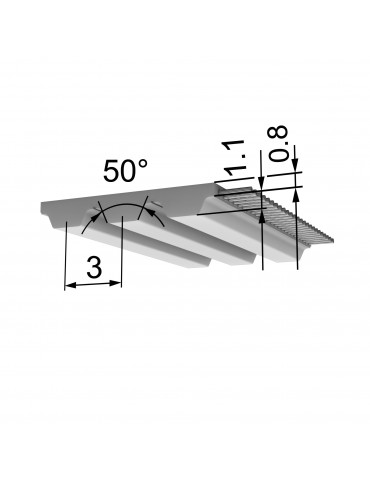

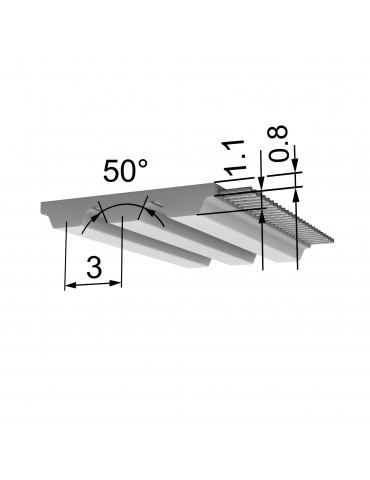

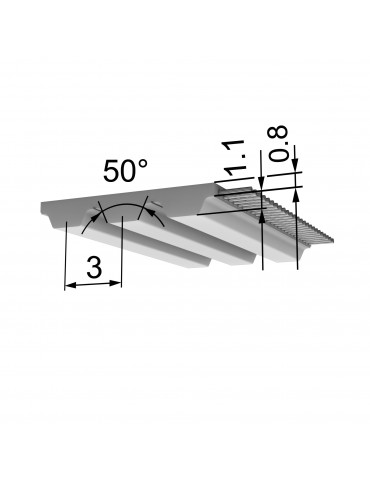

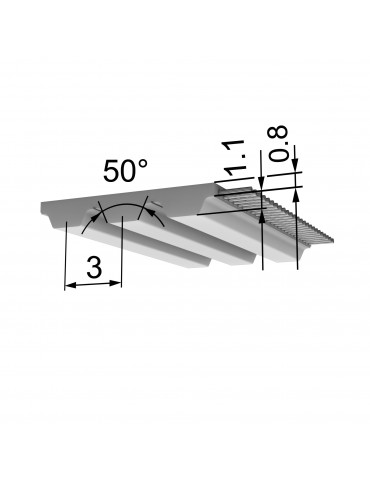

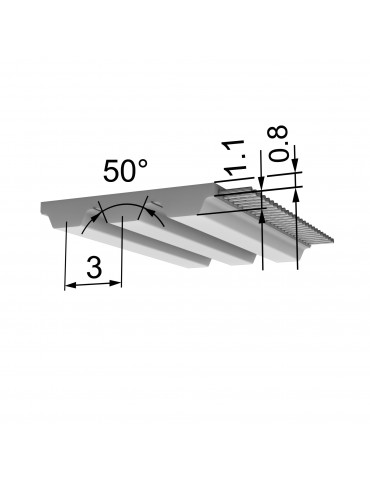

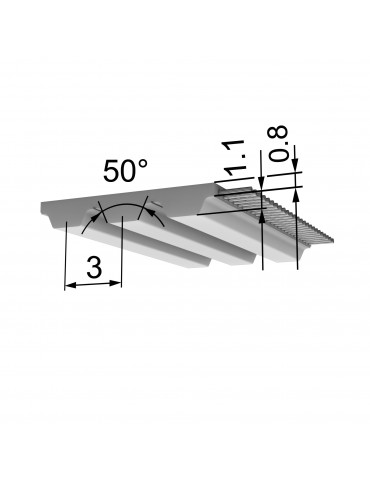

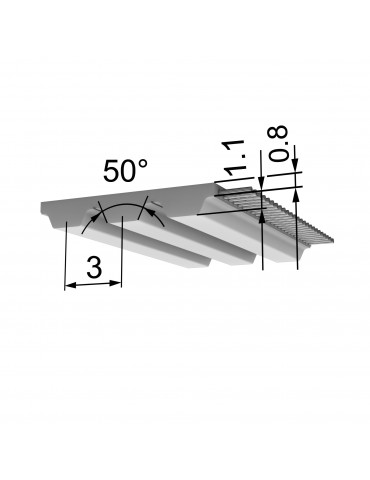

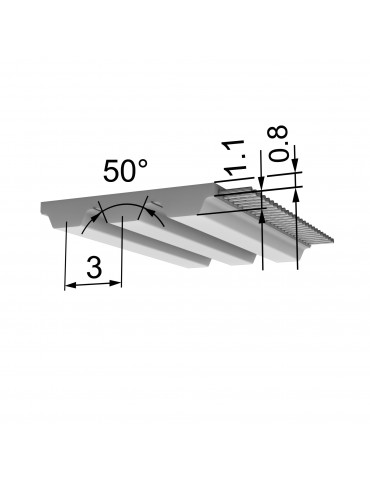

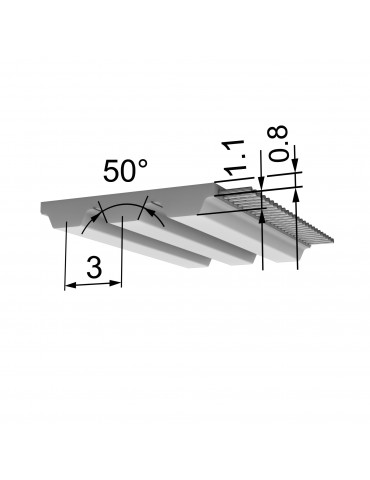

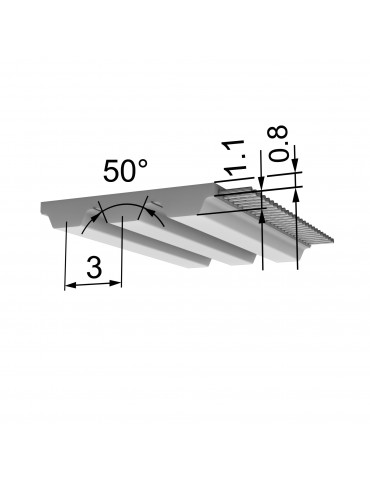

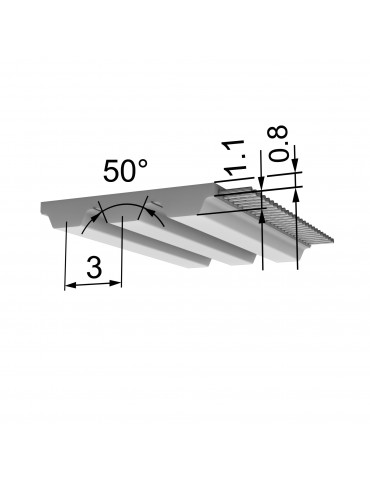

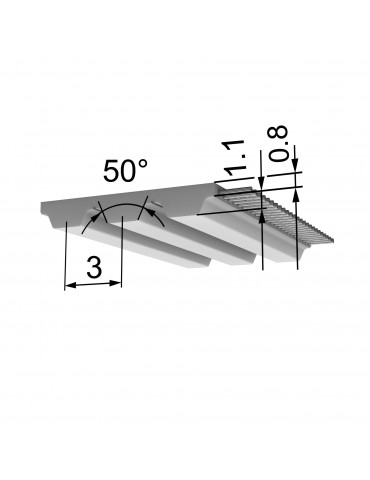

The performance welded BRECO® belt is characterized by its specific SFAT profile. Offset teeth give it a better meshing and autoguiding.

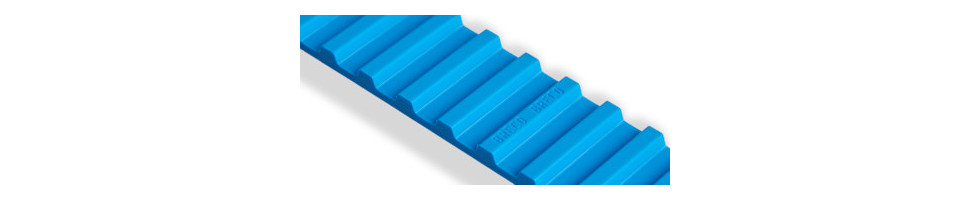

The CONTI® Synchrodrive welded joint belt is characterized by its rounded toothing profile. It is suitable for simple transport applications with small winding diameters. It can thus evolve with a weak pretension on the frame.

Finally, the BRECO® Plate welded joint belt is suitable for conveying applications that do not require synchronization. Moreover, this range of belts can be ennobled with a coating.